High-Density Barium Sulfate plates - Expert Shielding for Medical X-Ray Rooms

Whatsapp:

E-mail:

Category: Barium Sulfate Plate

High-Density Barium Sulfate plates - Expert Shielding for Medical X-Ray Rooms

Barium Sulfate Plate: Science and Applications of High-Performance Shielding Material

Chemical Composition & Material Properties

Barium sulfate plates are primarily composed of natural barium sulfate (BaSO₄), manufactured through high-temperature sintering and polymer composite technology. Key features include:

- High Density: 4.3-4.5 g/cm³, offering radiation shielding efficiency close to lead (11.34 g/cm³) with lighter weight and eco-friendliness;

- Non-Toxicity: Free from lead, heavy metals, and radioactivity, compliant with RoHS and REACH regulations;

- Corrosion Resistance: Resists acids, alkalis, and moisture, suitable for humid or chemically aggressive environments;

- Machinability: Customizable via cutting, drilling, and lamination for complex installations.

Mechanical Properties

1. Compressive Strength: ≥35 MPa, suitable for load-bearing walls or structures;

2. Flexibility: Bending strength >15 MPa, adaptable to curved surfaces;

3. Temperature Resistance: Stable performance from -30°C to +120°C;

4. Fire Rating: UL94 V-0, flame-retardant with no toxic emissions.

Applications

1. Medical Radiation Shielding

- X-ray room walls, CT suite doors/windows;

- Lead-free mobile shields, DR equipment partitions.

2. Industrial & Nuclear Protection

- Nuclear power plant control rooms, radioactive labs;

- Industrial radiography shields, isotope storage units.

3. Architectural Acoustics

- Soundproof walls for studios and conference rooms;

- Noise barriers in railways and airports.

4. Specialized Industrial Uses

- Anti-corrosion linings for chemical equipment;

- Thermal radiation shields for high-temperature machinery.

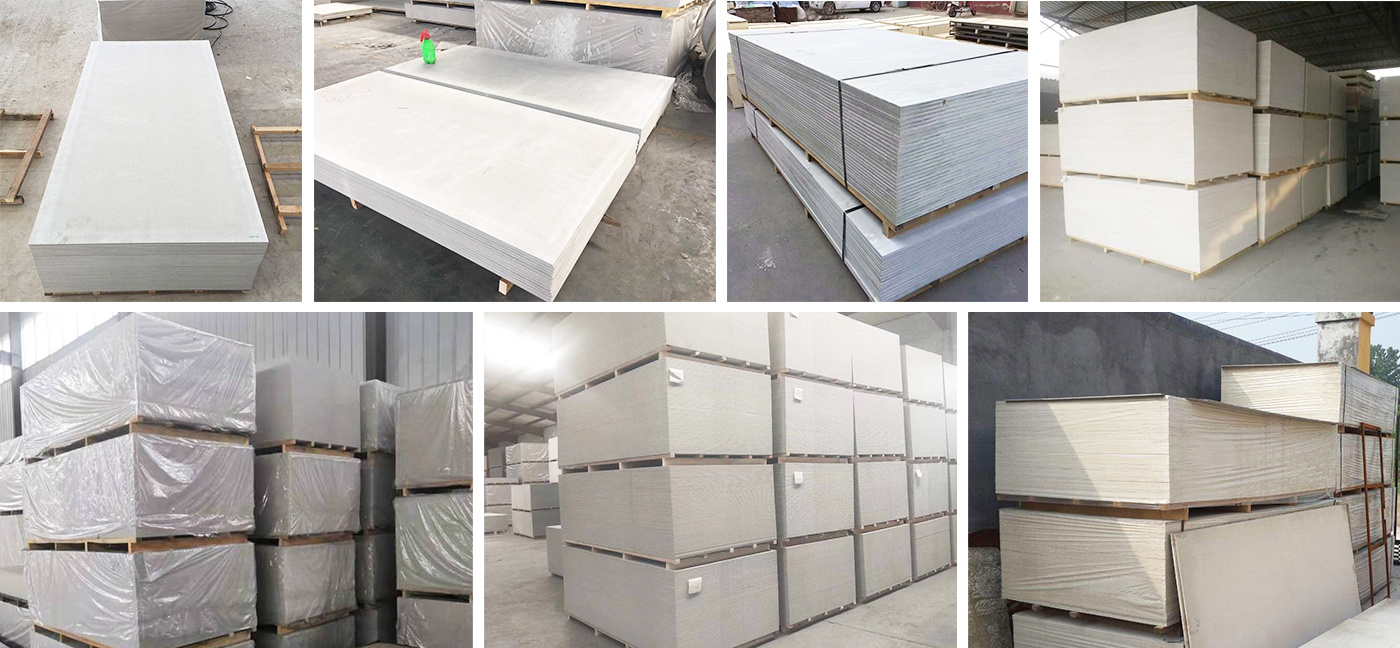

Packing and delivery

Keywords: High-Density Barium Sulfate plates - Expert Shielding for Medical X-Ray Rooms

Next page: None

Client Feedback

Quality Service And Excellent Team

FAQ

Can you customize special specifications of lead rods?

Requirements such as diameter, length, purity, surface treatment, etc. need to be provided, and some need to pay for molds or meet the minimum order quantity.

Can the dimensions of the lead plate be customized?

Sure, the size specifications of lead plates can usually be customized according to the specific needs of customers. Both length, width, and thickness can be produced according to requirements to meet the installation and usage requirements of different projects.

What are the common thicknesses of lead plates?

Common lead plate thicknesses include 0.5mm, 1.0mm, 1.5mm, 2.0mm, 2.5mm, 3.0mm, etc. Of course, lead plates of other special thicknesses can also be customized according to different application needs.

What is the density of lead sheet?

The density of lead is about 11.34 g/cm3, and the density of the lead plate is roughly in this range, which makes the lead plate have a good ability to shield rays.

What are the main components of lead sheet?

The main component of lead sheet is metal lead, which usually contains a small amount of other elements, such as antimony, tin, etc., to improve the performance of lead sheet.

Hot Products