High-Performance Copper-Clad Flat Steel for Grounding: The Preferred Choice for Reliable Grounding Grids

Whatsapp:

E-mail:

Category: Copper Flat Bar

High-Performance Copper-Clad Flat Steel for Grounding: The Preferred Choice for Reliable Grounding Grids

Copper Clad Steel Earthing Tape (Common) / Copper Clad Steel Grounding Tape (North America) / CCS Earthing Tape / CCS Grounding Tape / Copper-Bonded Steel Earthing Strip / Copper-Clad Earth Tape Conductor

Copper Clad Steel (CCS) Earthing Tape is a vital grounding material extensively used in power systems, lightning protection, and the construction of grounding grids for large facilities. It uniquely combines the excellent electrical conductivity and corrosion resistance of copper with the high mechanical strength and cost-effectiveness of steel. It is particularly suited as a horizontal grounding electrode for forming grounding grids or serving as a main bonding conductor to connect vertical electrodes (like earth rods).

Core Structure & Material:

Form: Typically a long, flat strip with a rectangular cross-section. Its flat shape provides a larger surface area compared to round rods of equivalent cross-section, enhancing soil contact and lowering earth resistance, especially for shallow burial or in favorable soil conditions.

Material: Manufactured using Copper Clad Steel (CCS) technology. A core of high-strength, low-carbon steel strip is metallurgically bonded (e.g., via hot-rolling or electroplating) to a continuous, dense layer of high-purity copper (typical thickness ≥0.25mm). This structure ensures:

Conductivity: The copper surface provides an excellent conductive path.

Strength & Toughness: The steel core provides high tensile strength and mechanical toughness, enabling the tape to withstand soil pressure, thermal stresses, and handling during installation (pulling, stretching, bending) without breaking.

Corrosion Resistance: The copper layer offers superior corrosion resistance in most soil environments, resulting in a long service life (typically designed for 30+ years), far exceeding galvanized steel strip.

Cost-Effectiveness: Significantly lower cost than solid copper tape while meeting performance requirements for most grounding applications.

Primary Functions & Advantages:

Forms Low-Resistance Ground Grids: As a horizontal electrode, it is laid over large areas underground (typically 0.5m - 1m deep) to create effective grounding grids, dramatically increasing the system's dispersion area and lowering overall earth resistance.

Provides Reliable Bonding: Acts as a "backbone" or "equipotential bonding strip" for the grounding system, reliably interconnecting multiple vertical electrodes (e.g., CCS rods), equipment grounding terminals, building foundation steel, etc., to form a complete equipotential network. Its flat shape facilitates secure connections using specialized clamps (e.g., CCS grounding clamps) or exothermic welding.

Dissipates Currents: Safely dissipates fault currents, lightning currents, and stray currents into the earth.

High Mechanical Strength: Ideal for long-distance runs requiring tension (e.g., on slopes, rocky terrain, or as support for lightning air terminals) and maintaining integrity in areas prone to ground settlement.

Ease of Installation: The tape form simplifies transportation, laying, and connection. It can be easily bent to follow contours and is suitable for trenching or direct burial.

Long Corrosion-Resistant Life: The protective copper layer ensures long-term stability and low maintenance in diverse soil conditions.

Typical Applications:

Grid conductors and bonding straps in large grounding grids for power plants and substations.

Ring grounding systems for transmission line towers and substation structures.

Grounding meshes/equalization grids for telecom base stations and data centers.

Lightning protection and static control grounding grids in petrochemical plants and tank farms.

Bonding conductors for railway signaling systems and airport runway lighting.

Foundation electrodes and equipotential bonding strips for large buildings (high-rises, factories).

Horizontal counterpoise conductors interconnecting multiple vertical rod electrodes (arrays).

Selection & Installation Key Points:

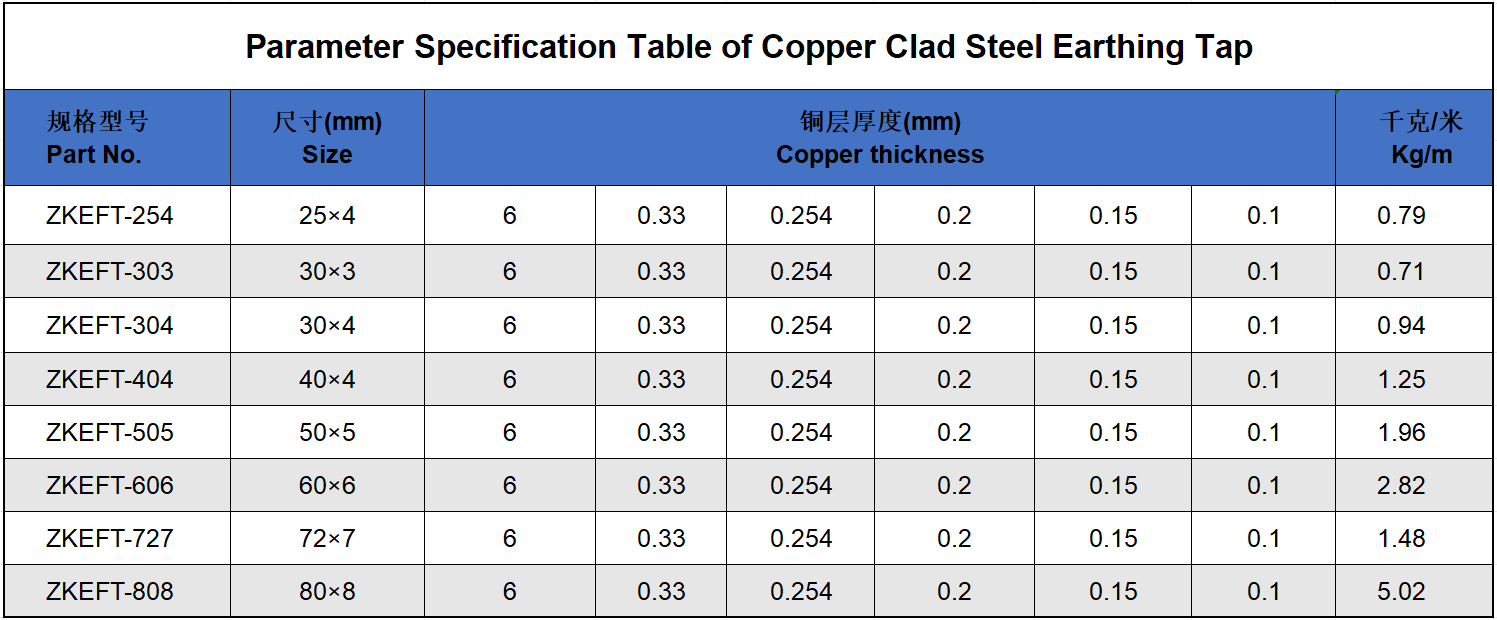

Specification: Select appropriate width (e.g., 30mm, 40mm, 50mm), thickness (e.g., 3mm, 4mm), and copper cladding thickness based on design requirements.

Connection: Use compatible corrosion-resistant connectors (e.g., bronze or stainless steel CCS grounding clamps) or exothermic weld (Cadweld) to ensure low-resistance, mechanically sound, and corrosion-protected joints.

Installation: Typically buried below the frost line; backfill should be compacted. Consider thicker copper cladding or tinned products in highly corrosive soils.

Testing: Perform earth resistance testing after installation and during periodic maintenance.

Conclusion: Copper Clad Steel Earthing Tape, with its unique copper-steel composite structure, outstanding electrical and mechanical properties, cost-effectiveness, and long life, is a preferred material for constructing efficient, reliable, and economical large-scale horizontal grounding networks. It is an indispensable foundational component in modern grounding system engineering.

Copper Clad Steel Earthing Tap product display and export packaging

Keywords: High-Performance Copper-Clad Flat Steel for Grounding: The Preferred Choice for Reliable Grounding Grids

Previous page: Copper-Bonded Grounding Flat Bar: Excellent Conductivity and Extended Corrosion Resistance

Next page: None

Client Feedback

Quality Service And Excellent Team

FAQ

Can you customize special specifications of lead rods?

Requirements such as diameter, length, purity, surface treatment, etc. need to be provided, and some need to pay for molds or meet the minimum order quantity.

Can the dimensions of the lead plate be customized?

Sure, the size specifications of lead plates can usually be customized according to the specific needs of customers. Both length, width, and thickness can be produced according to requirements to meet the installation and usage requirements of different projects.

What are the common thicknesses of lead plates?

Common lead plate thicknesses include 0.5mm, 1.0mm, 1.5mm, 2.0mm, 2.5mm, 3.0mm, etc. Of course, lead plates of other special thicknesses can also be customized according to different application needs.

What is the density of lead sheet?

The density of lead is about 11.34 g/cm3, and the density of the lead plate is roughly in this range, which makes the lead plate have a good ability to shield rays.

What are the main components of lead sheet?

The main component of lead sheet is metal lead, which usually contains a small amount of other elements, such as antimony, tin, etc., to improve the performance of lead sheet.

Hot Products