High-Quality Copper-Clad Ground Rods: The Optimal Choice for Safe Grounding

Whatsapp:

E-mail:

Category: Copper Earth Rod

High-Quality Copper-Clad Ground Rods: The Optimal Choice for Safe Grounding

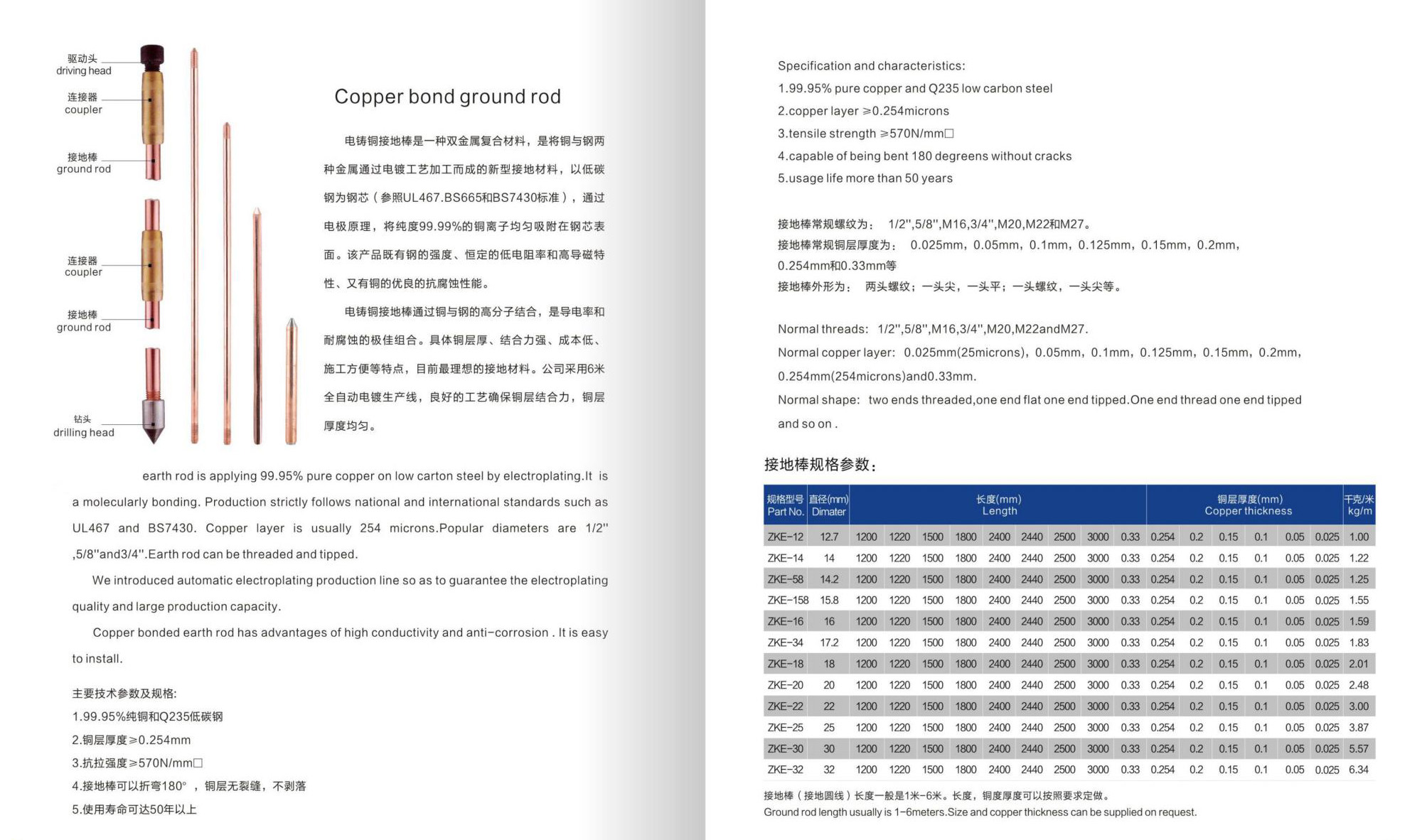

Copper Earth Rod (General Term) / Copper Grounding Rod (North American Preference) / Copper Earthing Rod (UK, Australia, etc. Preference) / Copper-Clad Steel Ground Rod (Specific to Composite Material)/

The Copper Earth Rod (encompassing the terms Grounding Rod and Earthing Rod) is a fundamental component crucial for electrical safety, lightning protection (LPS), and the reliable operation of electronic equipment. Its primary function is to establish a permanent, low-impedance electrical path that safely and effectively dissipates fault currents from power systems, high-energy lightning strike currents, and stray interference currents into the earth mass. This protects personnel, prevents equipment damage, maintains system stability, and ensures earth resistance meets safety code requirements.

Typically a solid cylindrical rod (occasionally hollow), it features robust threads on one or both ends for extension or cable connection. Core materials are:

High-Purity Electrolytic Copper: Offers exceptional conductivity (second only to silver), minimizing resistance in the dissipation path for optimal performance.

Copper-Clad Steel (CCS): Combines a thick copper layer (usually ≥0.25mm) metallurgically bonded to a strong low-carbon steel core. The copper provides superior conductivity and corrosion resistance, while the steel core grants very high mechanical strength (tensile strength far exceeding pure copper). This allows driving into hard or rocky soils without bending/breaking, making it the prevalent cost-effective solution balancing performance and strength. Tinning is an option for enhanced protection in highly corrosive soils.

Operating Principle: The rod is driven vertically/angled deep into the ground, penetrating high-resistivity surface layers to reach moister, lower-resistivity, stable subsoil. When fault currents, lightning currents, or interference currents occur, they flow via down conductors to the rod. Leveraging copper's top-tier conductivity and the rod's substantial soil contact area, currents are dissipated rapidly into the vast earth with very low resistance. Key roles include: Preventing electric shock (rapidly lowering equipment enclosure potential), Protecting equipment (diverting lightning/overvoltages), Stabilizing systems (providing reference potential, suppressing interference), and Complying with mandatory safety codes (e.g., IEC, NEC, IEEE, GB).

Core Advantages:

Exceptional Conductivity: Copper's high conductivity is fundamental for low earth resistance.

Superior Corrosion Resistance: Copper is stable and resistant in soil; CCS rods last over 30 years with intact cladding, far exceeding galvanized steel.

High Mechanical Strength (CCS): Essential for deep driving or challenging soil (hard, rocky).

Reliable Connections: Threaded design ensures secure, low-resistance, durable connections.

Long-Term Stability: Material stability ensures reliable performance.

Applications are vast: Power plants/substations, building power/lightning protection, telecom sites/equipment rooms, transportation infrastructure (railways/airports), petrochemical areas (lightning/static control), renewable energy sites (solar/wind), and sensitive electronic equipment grounding. Installation requires attention to site selection (low-resistivity soil), depth (typically ≥2.5-3m), connection reliability, and periodic earth resistance testing. Selection depends on soil conditions, current dissipation needs, strength requirements, and budget. In essence, the copper earth rod utilizes copper's superior properties to create a "safe conduit" for hazardous currents into the earth, forming an indispensable cornerstone of modern electrical safety.

Display of copper-plated grounding rods and export packaging

Keywords: High-Quality Copper-Clad Ground Rods: The Optimal Choice for Safe Grounding

Next page: None

Client Feedback

Quality Service And Excellent Team

FAQ

Can you customize special specifications of lead rods?

Requirements such as diameter, length, purity, surface treatment, etc. need to be provided, and some need to pay for molds or meet the minimum order quantity.

Can the dimensions of the lead plate be customized?

Sure, the size specifications of lead plates can usually be customized according to the specific needs of customers. Both length, width, and thickness can be produced according to requirements to meet the installation and usage requirements of different projects.

What are the common thicknesses of lead plates?

Common lead plate thicknesses include 0.5mm, 1.0mm, 1.5mm, 2.0mm, 2.5mm, 3.0mm, etc. Of course, lead plates of other special thicknesses can also be customized according to different application needs.

What is the density of lead sheet?

The density of lead is about 11.34 g/cm3, and the density of the lead plate is roughly in this range, which makes the lead plate have a good ability to shield rays.

What are the main components of lead sheet?

The main component of lead sheet is metal lead, which usually contains a small amount of other elements, such as antimony, tin, etc., to improve the performance of lead sheet.

Hot Products