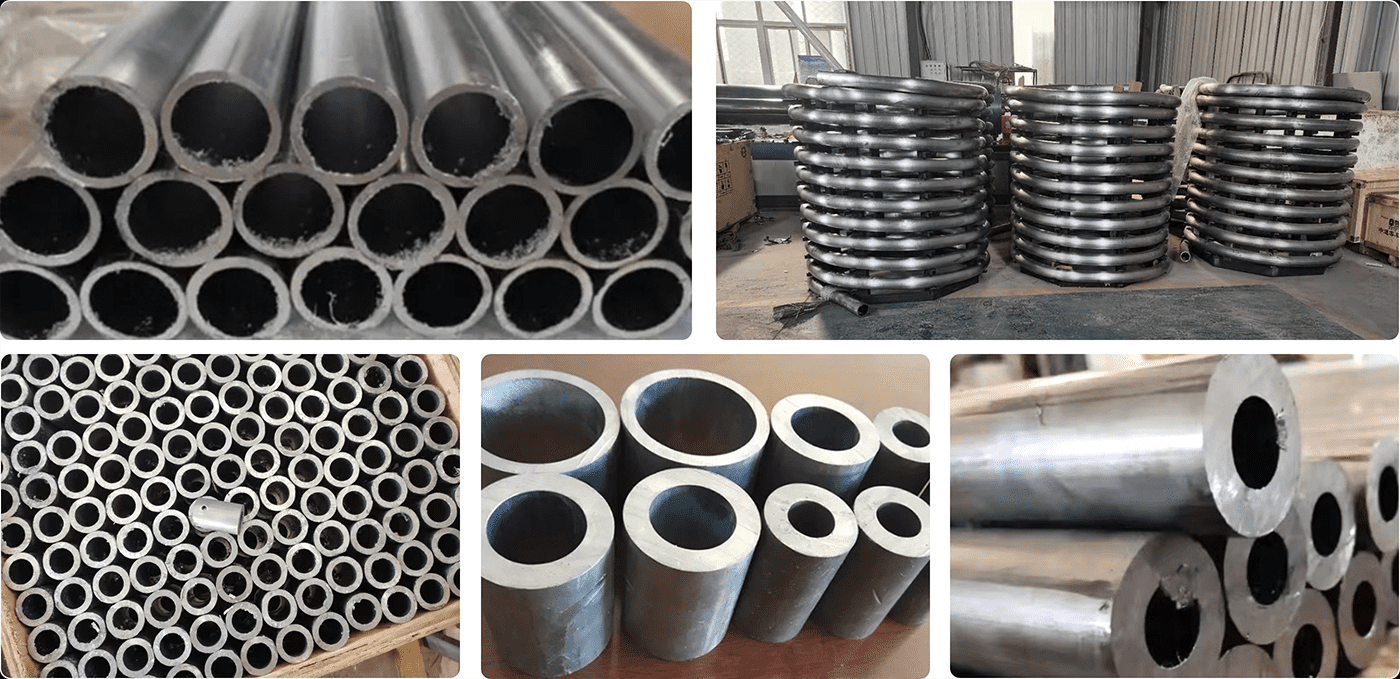

Lead tube

Whatsapp:

E-mail:

Category: Lead tube

Lead tube

Chemical Composition

Lead tubes typically consist of high-purity lead (Pb) with commercial grades exceeding 99.97% purity, while pharmaceutical-grade tubes may reach 99.99% purity. Trace impurities are strictly controlled: antimony ≤0.005%, tin ≤0.002%, copper ≤0.001%, and zinc ≤0.001% (ASTM B29-18). For specialized corrosion-resistant applications, alloys may contain 0.5-2% antimony to enhance strength, with lead-tin alloys (1-5% Sn) used in low-temperature sealing applications. The chemical composition ensures compliance with ISO 6127:2017, where total impurities in lead tubes for industrial use are limited to 0.03%.

Mechanical Properties

Lead tubes exhibit defined mechanical characteristics suitable for diverse applications. The tensile strength ranges from 14-18 MPa (ASTM E8), with a yield strength of 12-15 MPa and an elongation at break of 40-60% (ISO 6892). The Vickers hardness (HV) is 4-6, allowing easy forming with a maximum working pressure of 0.6 MPa for seamless lead tubes (BS EN 12666:2016). The melting point is 327.46°C, and thermal conductivity is 35.3 W/(m·K) at 20°C. With a density of 11.34 g/cm³, lead tubes have a hydrostatic burst pressure of 2.5-4 MPa for 10-20 mm diameter tubes (DIN 17861), critical for pressure-bearing applications.

Applications

Lead tubes demonstrate data-backed utility across industries:

- Radiation Shielding: Medical CT scanners use 2-5 mm thick lead tubes for cable shielding, blocking 95% of 120 kVp X-rays (NCRP Report 147). Nuclear laboratories employ 10-20 cm diameter lead tubes for radioactive material transport, achieving 99% gamma ray attenuation.

- Corrosion-Resistant Piping: In chemical plants, lead tubes (ASTM B876) with 6-12 mm wall thickness resist 98% sulfuric acid at 60°C, with a service life exceeding 20 years. Pharmaceutical-grade lead tubes (USP 23) are used for distilled water transport, meeting heavy metal content limits (<10 ppm).

- Electrical Insulation: Lead-sheathed cables (BS 6622) use 0.5-1 mm lead tubes, providing moisture protection with a dielectric strength of 15 kV/mm. Submarine cables employ 3-5 mm lead tubes, maintaining electrical integrity at depths up to 2,000 meters.

- Architectural Applications: Decorative lead tubes (BS EN 12588) for stained glass windows have outer diameters of 3-8 mm, with a tensile strength sufficient to support 5-10 kg/m² glass loads, lasting over 100 years in outdoor environments.

Packing and delivery

Keywords: Lead tube

Previous page: None

Client Feedback

Quality Service And Excellent Team

FAQ

Can you customize special specifications of lead rods?

Requirements such as diameter, length, purity, surface treatment, etc. need to be provided, and some need to pay for molds or meet the minimum order quantity.

Can the dimensions of the lead plate be customized?

Sure, the size specifications of lead plates can usually be customized according to the specific needs of customers. Both length, width, and thickness can be produced according to requirements to meet the installation and usage requirements of different projects.

What are the common thicknesses of lead plates?

Common lead plate thicknesses include 0.5mm, 1.0mm, 1.5mm, 2.0mm, 2.5mm, 3.0mm, etc. Of course, lead plates of other special thicknesses can also be customized according to different application needs.

What is the density of lead sheet?

The density of lead is about 11.34 g/cm3, and the density of the lead plate is roughly in this range, which makes the lead plate have a good ability to shield rays.

What are the main components of lead sheet?

The main component of lead sheet is metal lead, which usually contains a small amount of other elements, such as antimony, tin, etc., to improve the performance of lead sheet.

Hot Products